Quickdraw offers a variety of accessories to help optimize your conveyor system, improve efficiency, and solve a wide range of application needs.

-

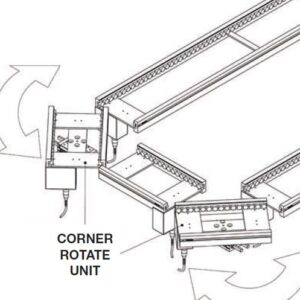

Corner Rotate

View Details -

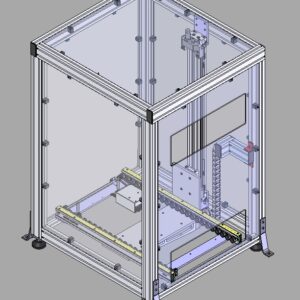

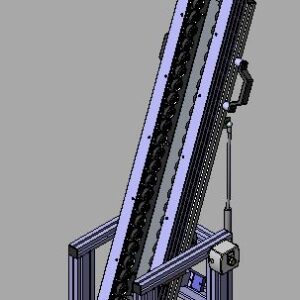

Elevator

View Details -

Escapement Stops

View Details -

Framing/Leg Sets

View Details -

Lift and Locate

View Details -

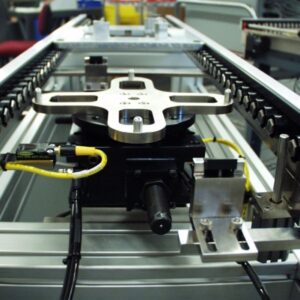

Lift and Rotate

View Details -

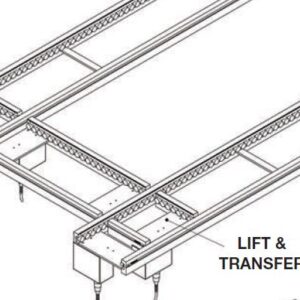

Lift and Transfer

View Details -

Lift Gate

View Details -

Metering Stops

View Details -

Product Pushers

View Details -

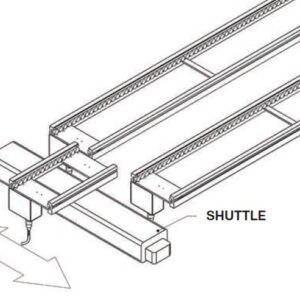

Shuttle

View Details -

Stacker/De-Stacker

View Details